The LNC860E series inverter is a general-purpose high-performance vector inverter, which is mainly used to control and adjust the speed and torque of three-phase AC synchronous motor. It adopts 32-bit DSP chip with built-in core control algorithms such as closed-loop loss control, open-loop vector control and torque control.

Summary

The LNC860E series inverter is a general-purpose high-performance vector inverter, which is mainly used to control and adjust the speed and torque of three-phase AC synchronous motor. It adopts 32-bit DSP chip with built-in core control algorithms such as closed-loop loss control, open-loop vector control and torque control. It can realize the body motion control of hydro-magnetic synchronous motor with higher living energy and accuracy, low speed and high torque output, good dynamic characteristics and super overload capability, and supports a variety of PG cards. While improving the reliability and environmental adaptability of products, it also strengthens the design of customer's image and industry specialization, with more optimized functions, more flexible application and more stable performance. It can be widely used in injection molding machines, air compressors, medium and large power clothing systems, CNC machining centers, lifting equipment, textile equipment and other high-end products Application occasion.

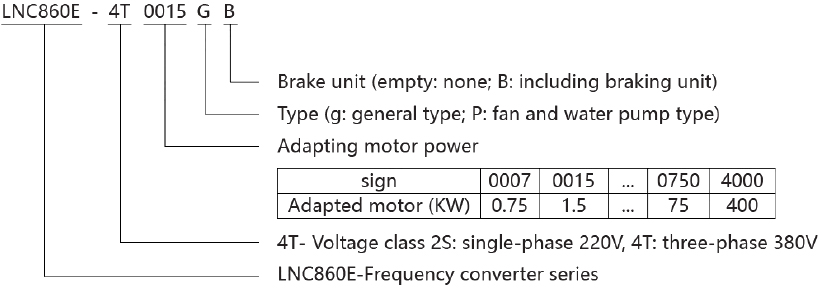

Type meaning

Product features

● Open-loop vector and closed-loop vector control of permanent magnet motor

● Supports a variety of encoders: ABZ incremental, UVW incremental and rotary.

● Wide voltage input, automatic voltage stabilization of output voltage (AVR), instant power failure without stopping, stronger adaptability.

● Support multiple frequency settings: digital setting, analog setting, PID setting, RS485 communication setting, smooth start and stable operation, speed tracking function, sharing DC bus, saving electric energy, low noise and strong anti-interference ability.

● Strong overload capacity, 150% rated torque can run for 60 seconds.

● Built-in advanced PID algorithm, fast response, strong adaptability and simple debugging.

● 16-stage speed control, simple PLC realizes multi-functional logic control such as timing, fixed speed and orientation.

● Multiple protection functions: over-voltage, over-current, overload, overheating, etc. A supports the display and operation of Chinese and English LCD panels.

● A supports Profibus-DP and MODBUS communication.

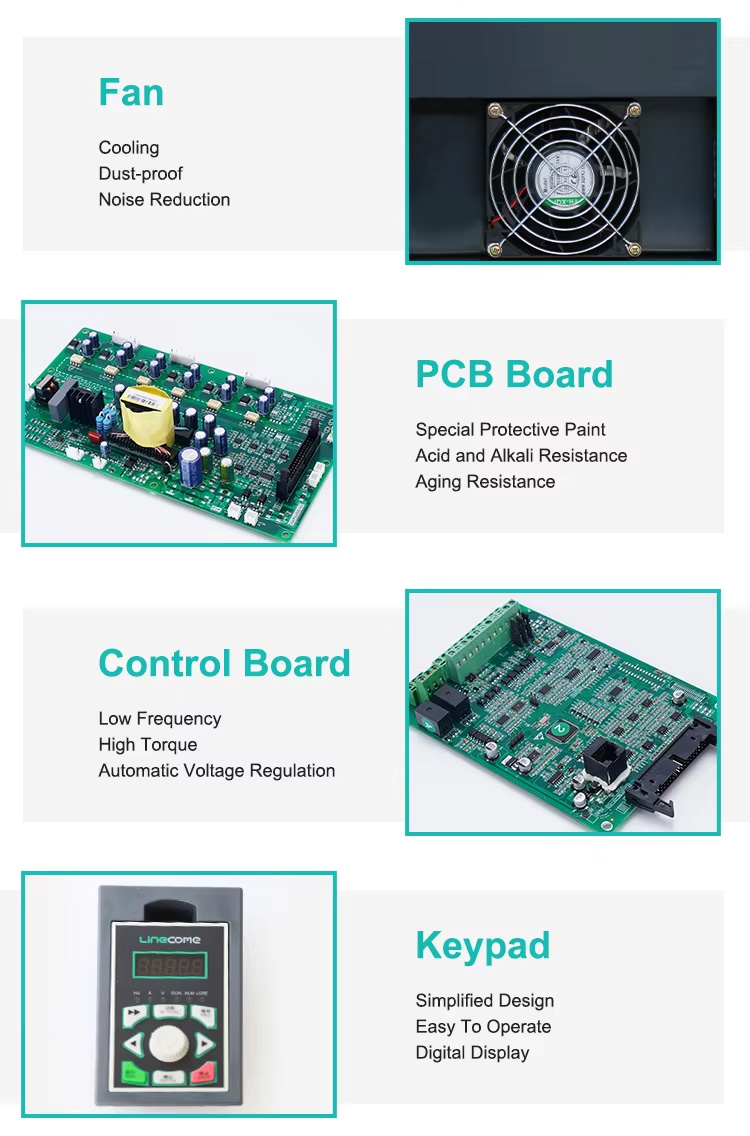

● The structure is designed with independent air duct, the fan can be disassembled freely, and the heat dissipation is good.

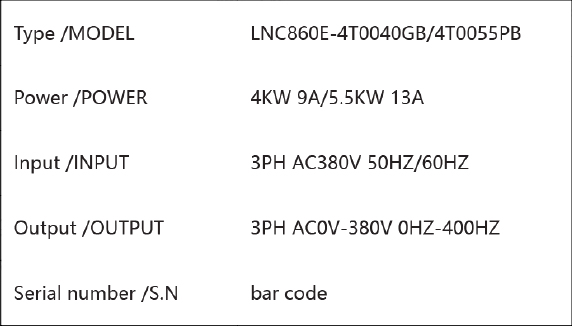

Nameplate

LNC860EList of series models

Frequency Converter Model | Power Supply Capacity (Kva) | Input Current (A) | Output Current (A) | Adapted Motor (Kw) |

Three- Phase Power Supply: 380V+15%,50/60Hz | ||||

LNC860E-4T0007GB | 1.5 | 3.4 | 2.1 | 0.75 |

LNC860E-4T0015GB | 3.0 | 5.0 | 3.8 | 1.5 |

LNC860E-4T0022GB | 4.0 | 5.8 | 5.1 | 2.2 |

LNC860E-4T0040GB | 5.9 | 10.5 | 9 | 3.7 |

LNC860E-4T0055GB | 8.9 | 14.6 | 13 | 5.5 |

LNC860E-4T0075GB | 11 | 20.5 | 17 | 7.5 |

LNC860E-4T0110GB | 17 | 26 | 25 | 11 |

LNC860E-4T0150GB | 21 | 35 | 32 | 15 |

LNC860E-4T0185GB | 24 | 38.5 | 37 | 18.5 |

LNC860E-4T0220GB | 30 | 46.5 | 45 | 22 |

LNC860E-4T0300GB | 40 | 62 | 60 | 30 |

LNC860E-4T0370GB | 57 | 76 | 75 | 37 |

LNC860E-4T0450GB | 69 | 92 | 91 | 45 |

LNC860E-4T0550GB | 85 | 113 | 112 | 55 |

LNC860E-4T0750GB | 114 | 157 | 150 | 75 |

LNC860E-4T0900GB | 134 | 180 | 176 | 90 |

LNC860E-4T1100GB | 160 | 214 | 210 | 110 |

LNC860E-4T1320GB | 192 | 256 | 253 | 132 |

LNC860E-4T1600GB | 231 | 307 | 304 | 160 |

LNC860E-4T2000GB | 250 | 385 | 377 | 200 |

LNC860E-4T2200GB | 280 | 430 | 426 | 220 |

LNC860E-4T2500GB | 355 | 440 | 465 | 250 |

LNC860E-4T2800GB | 396 | 495 | 520 | 280 |

LNC860E-4T3150GB | 445 | 65 | 585 | 315 |

LNC860E-4T3550GB | 500 | 617 | 650 | 355 |

LNC860E-4T4000GB | 565 | 687 | 725 | 400 |

Technological specification

Project | specifications | |

control characteristic | Output frequency | 0-500Hz |

carrier frequency | 0.8kHz~12kHz can automatically adjust the carrier frequency according to the load characteristics. | |

Output frequency resolution | 0.01Hz | |

Control mode | Open-loop vector control (SVC) | |

Torque characteristic | With torque compensation and slip compensation, the starting torque can reach 150% at 0.5Hz | |

Torque control accuracy | ±5% (FVC) | |

Overvoltage loss rate prevention protection | Set as a percentage of rated current, 20~250% | |

Speed range | 1:100 (SVC) 1:1000(FVC) | |

Steady speed accuracy | ±0.5%(SVC) | |

overload capacity | 150% rated output current for one minute | |

V/F curve | Four ways: linear; Multipoint type; Complete V/f separation; Incomplete V/f separation | |

Acceleration and deceleration curve | line or s-curve acceleration and deceleration mode; Four kinds of acceleration and deceleration time; The acceleration and deceleration time range is 0.1~6500.0s | |

DC braking | DC braking frequency: 0.00Hz~ ~ maximum frequency, braking time: 0.0s~60.0s, braking action current value: 0.0%~100.0%. | |

Inching control | Inching frequency range: 0.00Hz~ ~ maximum frequency; The inching acceleration and deceleration time is 0.1s~6500.0s | |

Simple PLC, multi-speed operation | Realized by the built-in PLC or control terminal to realize the maximum 16-stage speed operation. | |

Built in PID | The closed-loop control system of process control can be conveniently | |

Automatic voltage regulation (AVR) | When the grid voltage changes, it can automatically keep the output voltage constant. | |

fast current limiting function | Minimize overcurrent fault and protect the normal operation of frequency converter. | |

operating characteristic | Run command channel | Three channels: operation panel, control terminal and serial communication port. It can be switched in many ways. |

frequency source | 10 frequency sources: panel knob, operation panel, analog voltage, analog current, RS485 communication, Multi-speed, PID simple PLC, which can be switched in many ways. | |

Auxiliary frequency source | 10 kinds of auxiliary frequency sources. Can flexibly realize auxiliary frequency fine tuning and frequency synthesis. | |

input terminal | Five digital input terminals that can flexibly realize auxiliary frequency fine tuning and frequency synthesis, one of which can be used as high-speed pulse input, | |

output terminal | A high-speed pulse output terminal, square wave signal output of OkHz~50kHz, can realize the output of physical quantities such as set frequency and output frequency. | |

Show and keyboard operation | Led display | There are 8 function keys, 5-position 7-segment LED and 5 status LED indicators, which can perform forward rotation, reverse rotation, reset, stop, jog, parameter setting and display. |

Protection characteristics | Protection function | Power-on motor short-circuit detection, input and output open-phase protection, overcurrent protection, overvoltage protection, undervoltage protection, overheat protection, overload protection, short-circuit protection, etc. |

Other characteristics | Optional card | IO expansion card, communication card (isolated), PG card |

Multiple encoder support | Support differential, open collector, UVW, resolver | |

environment | Place of use | Indoor, free from direct sunlight, free of dust, corrosive gas, combustible gas, oil mist, water vapor, dripping water or salt, etc. |

altitude | content less than 1000m | |

ambient temperature | -10℃~+40℃ (ambient temperature is 40℃~50℃, please use it in a derated way) | |

humidity | less than 95%RH, and no water condensation | |

Vibration | less than 5.9m/s2(0.6g). | |

Storage temperature | -20℃~+60℃ | |

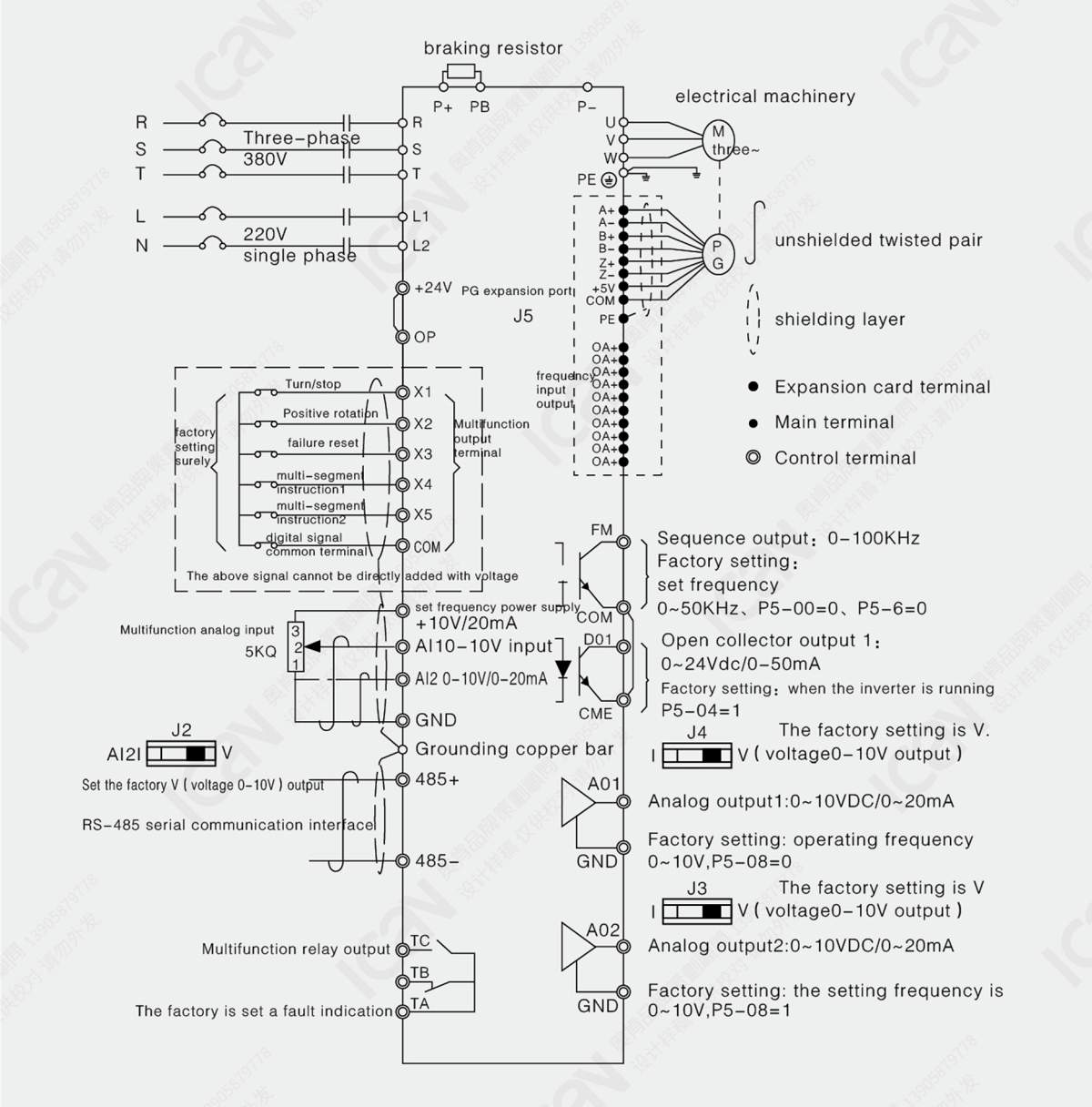

Basic wiring diagram

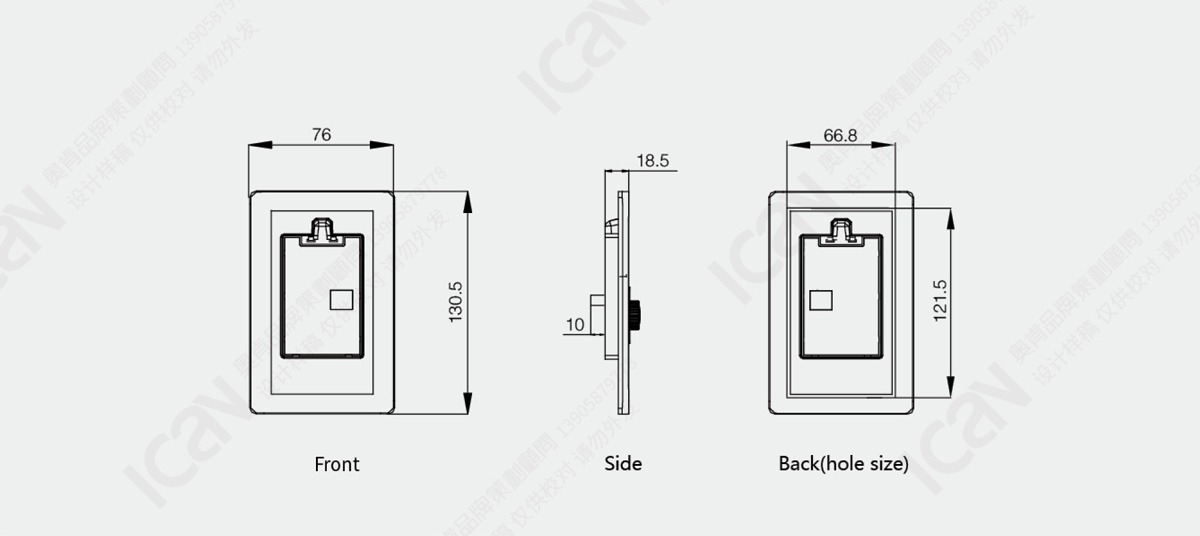

Installation dimensions of keyboard base

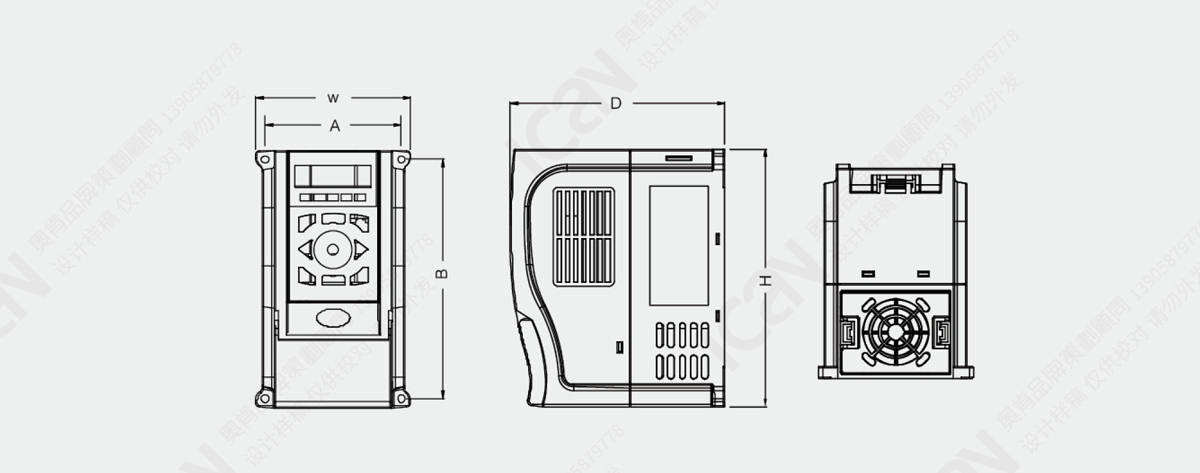

Schematic diagram of external dimensions and installation dimensions of plastic structure

Fixed Output Power | Input Voltage | A | B | H | W | D | Aperture |

0.75~2.2 | Three- phase | 90 | 157 | 170 | 101 | 142 | 5 |

4 | 111 | 183 | 197 | 129 | 175 | 5 | |

5.5~7.5 | 137 | 237 | 256 | 157 | 190 | 5 |

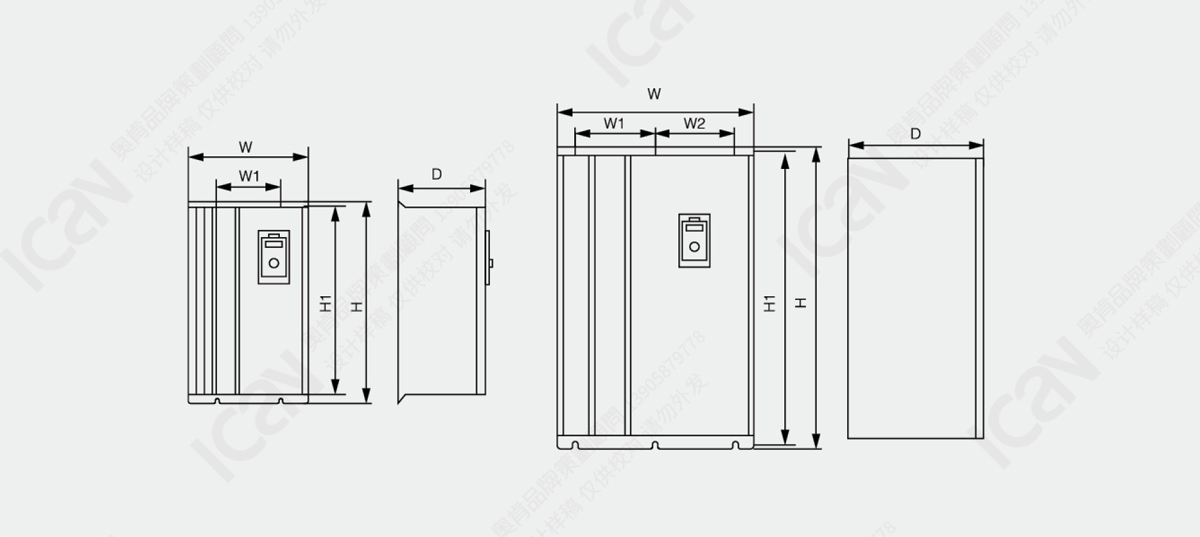

Schematic diagram of external dimensions and installation dimensions of sheet metal structure (hanging type)

| Hanging style | ||||||||||

Type | Exterior dimensions | Installation size | Aperture | |||||||

Kw | H(mm) | W(mm) | D(mm) | H1(mm) | W1(mm) | W2(mm) | mm | |||

11-15 | 340 | 204 | 214 | 325 | 150 | Φ6 | ||||

18.5-22 | 360 | 224 | 214 | 345 | 150 | Φ6 | ||||

30-37 | 460 | 260 | 264 | 440 | 200 | Φ8 | ||||

45-75 | 570 | 380 | 264 | 440 | 200 | Φ10 | ||||

90-132 | 570 | 380 | 263 | 547.5 | 240 | Φ12 | ||||

160-220 | 760 | 500 | 355 | 735 | 200 | 200 | Φ12 | |||

250-400 | 862 | 750 | 455 | 832 | 250 | 250 | Φ12 | |||

Sweep it

Linecome